Linear Low Density Polyethylene:

Linear low-density polyethylene is shortly known as LLDPE. LLDPE is a substantially linear polymer (polyethylene), with significant numbers of short branches, commonly made by copolymerization of ethylene with longer-chain of olefins. Linear low-density polyethylene differs structurally from predictable low-density polyethylene (LDPE) because of the absence of long chain branching.

Processing & Properties:

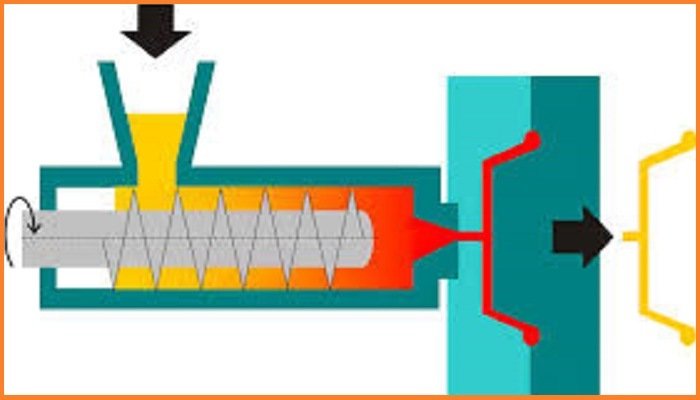

LLDPE has a unique melt flow properties. LLDPE is less shear sensitive because of its narrower molecular weight distribution and shorter chain branching. During a shearing process, such as extrusion, LLDPE remains more viscous than LDPE. The lower shear sensitivity of LLDPE allows for a faster stress relaxation of the polymer chains during extrusion, and, therefore, the physical properties are susceptible to changes in blow-up ratios. In melt extension, LLDPE has lower viscosity at all strain rates. As the deformation rate of the polyethylene increases.

Physical Properties:

| Properties | Nominal Values |

| Density | 0.88 – 0.915 gm/cc |

| Tensile Strength | 30 MPa |

| Flexural Modulus | 0.35 GPa |

| Izod Impact (Notched) | 1.06 KJ/M |

| Elongation at Break | 400% |

| Heat Distortion Temp. (Load@ 1.80 MPa) | 37 Deg C |

| Flammability UL94 | HB |

| Melting Temperature | 130-160 Deg C |

| Mould Shrinkage | Max. 3% |

| Mould Temperature | 20-60 Deg C |

| Operating Temperature | Max. 50 Deg C |

| Water Absorption | 0.01 % |

| Oxygen Index | Max. 17% |

Uses:

it is used for plastic bags and sheets, plastic wrap, stretch wrap, pouches, toys, covers, lids, pipes, buckets and containers, covering of cables, geomembranes & flexible tubes.

I want to know how much low temperature LLDPE FB2230 can with stand , if we want that material need to withstand at -50 deg c

Than what we need to

Please suggest