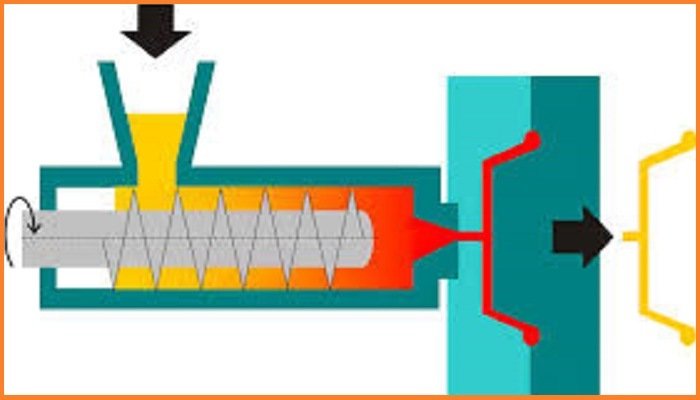

INJECTION MOLDING PROCESS:

Brief:

One of the most common methods of converting plastics from the raw materials form to an article of use is the process of injection moulding. This process is used for thermoplastic materials and other polymeric materials which may be successively melted, reshaped and cooled.

Injection moulded component are a future of almost very functional manufacture article in the modern world from automotive products through to food packaging. This versatile process allow used to produce high quality, simple and complex component on a fully automated basis at high speed with material that have change the face of manufacturing technology over the last 50 years or so. Injection moulding is suitable processing methods for following materials.

• Thermoplastic

• Elastomers

• Rubber

• Thermo set

• Composites

• Foamed plastics

Advantage of Injection Moulding Process:

• Parts can be produced at high production rate

• Large volume production is possible

• Relatively low labour cost per unit is obtainable

• Parts required little or no finishing

• Many different surfaces, colours and finishes are available

• Good decoration is possible

• For many shapes this process is the most economical way to fabricate

• Process permits the manufacture of very small parts which are almost possible to fabricate in quantities by other methods

• Minimal scrap loss result as runners, gates & rejects can be reground and reused

• Same item can be moulded in different material without changing the machine or mould is some cases

• Close dimensional tolerance can be maintained

• Parts can be moulded with metallic and non-metalic inserts

• Parts can be moulded in a combination of plastic and such fillers as glass, asbestos, talc and carbon

• The inherent properties of the material give many advantage such as high strength, weight rates, corrosion resistance, strength and clarity.

Limitation of Injection Moulding:

• Intense industry competition obtain results in no profits margins

• Mould cost are high

• Moulding machinery and auxiliary equipment cost are high

• Lack of knowledge about the fundamentals of the process causes problems

• Lack of knowledge about the long time properties of the materials may results in long time failures