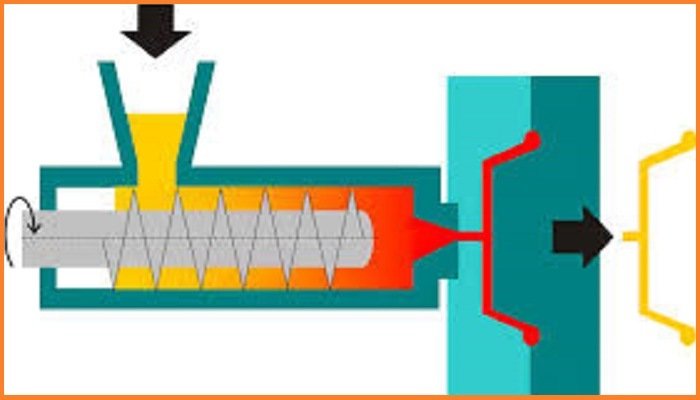

PET IN INJECTION MOLDING

PET bottles are a huge market for the material. Processing PET into bottles can take two steps depending on the application or bottle. In the first step, PET is injection molded into a “mini bottle,” complete with threads, called a pre-form. This pre-form is then reheated, stretched and blown into its final shape. While there is technology available that combines these two processes in a single step, for larger-throughput applications pre-form and bottle making are generally made in distinct steps, often by different processors.

For transparent PET pre-form mould, sometimes we would face up to with problems during pre-form molding period. Usually it would have problems like below also with solve ways.

- PET pre-form with bubble, it is mainly caused by not dried material and air during injection, suggest making material with drying and open air venting for molds.

- Surface not with good gloss, it is mainly due to mold surface not proper polishing, also with cooling earlier, it cause pre-form surface not same as mold surface, and with concave convex.

- Waves for pre-form, it is due to material with strong dynamic viscosity, front area the material is cold, and later material go over on the cold surface, so makes the surface with waves.

- Black pots on pre-form, it is mainly due to injection machine barrel, part area with over high temperature and make the material bad We offer not only PET pre-form mold, also the PET pre-form molding.

polymeracademy.com