Thermosetting polymer

A thermosetting polymer also called a thermoset, is a polymer that is irreversibly cured of a soft solid or viscous liquid prepolymer or resin. The process of curing changes the resin into an infusible, insoluble polymer network, and is induced by the action of heat or suitable radiation often under high pressure, or by mixing with a catalyst. Thermoset resins are usually malleable or liquid prior to curing and are often designed to be molded into their final shape, or used as adhesives. Others are solids like that of the molding compound used in semiconductors and integrated circuits. Once hardened a thermoset resin cannot be reheated and melted to be shaped differently. Thermosetting polymers may be contrasted with thermoplastic polymers, which are commonly produced in pellets, and shaped into their final product form by melting and pressing or injection molding.

Process

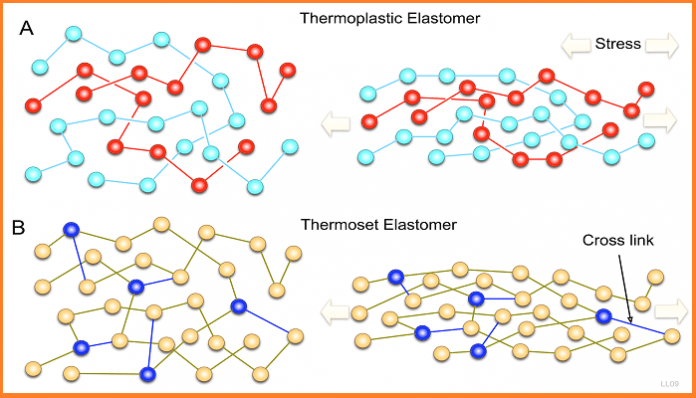

Curing a thermosetting resin transforms it into a plastic, or elastomer (rubber) by crosslinking or chain extension through the formation of covalent bonds between individual chains of the polymer. Crosslink density varies depending on the monomer or prepolymer mix, and the mechanism of crosslinking: Acrylic resins, polyesters and vinyl esters with unsaturated sites at the ends or on the backbone are generally linked by copolymerization with unsaturated monomer diluents, with cure initiated by free radicals generated from ionizing radiation or by the photolytic or thermal decomposition of a radical initiator – the intensity of crosslinking is influenced by the degree of backbone unsaturation in the prepolymer; Epoxy functional resins can be homo-polymerized with anionic or cationic catalysts and heat, or copolymerized through nucleophilic addition reactions with multifunctional crosslinking agents which are also known as curing agents or hardeners.

As reaction proceeds, larger and larger molecules are formed and highly branched crosslinked structures develop, the rate of cure being influenced by the physical form and functionality of epoxy resins and curing agents – elevated temperature post-curing induces secondary crosslinking of backbone hydroxyl functionality which condense to form ether bonds; Polyurethanes form when isocyanate resins and prepolymers are combined with low- or high-molecular-weight polyols, with strict stoichiometric ratios being essential to control nucleophilic addition polymerisation – the degree of crosslinking and resulting physical type (elastomer or plastic) is adjusted from the molecular weight and functionality of isocyanate resins, prepolymers, and the exact combinations of diols, triols and polyols selected, with the rate of reaction being strongly influenced by catalysts and inhibitors; polyureas form virtually instantaneously when isocyanate resins are combined with long-chain amine functional polyether or polyester resins and short-chain diamine extenders – the amine-isocyanate nucleophilic addition reaction does not require catalysts. Polyureas also form when isocyanate resins come into contact with moisture.

Phenolic, amino and furan resins all cure by polycondensation involving the release of water and heat, with cure initiation and polymerization exothermic control influenced by curing temperature, catalyst selection/loading and processing method/pressure – the degree of pre-polymerization and level of residual hydroxymethyl content in the resins determine the crosslink density.

Thermoset plastic polymers characterized by rigid, three-dimensional structures and high molecular weight, stay out of shape when deformed and undergo permanent or plastic deformation under load, and normally decompose before melting. Thermoset elastomers, which are soft and springy or rubbery and can be deformed and revert to their original shape on loading release, also decompose before melting.

Conventional thermoset plastics or elastomers therefore cannot be melted and re-shaped after they are cured which implies that thermosets cannot be recycled for the same purpose, except as filler material. There are developments however involving thermoset epoxy resins which on controlled and contained heating form crosslinked networks that can be repeatedly reshaped like silica glass by reversible covalent bond exchange reactions on reheating above the glass transition temperature.

There are also thermoset polyurethanes shown to have transient properties and which can thus be reprocessed or recycled. Thermosetting polymer mixtures based on thermosetting resin monomers and pre-polymers can be formulated and applied and processed in a variety of ways to create distinctive cured properties that cannot be achieved with thermoplastic polymers or inorganic materials. Application/process uses and methods for thermosets include protective coating, seamless flooring, civil engineering construction grouts for jointing and injection, mortars, foundry sands, adhesives, sealants, castings, potting, electrical insulation, encapsulation, 3D printing, solid foams, wet lay-up laminating, pultrusion, gelcoats, filament winding, pre-pregs, and molding.

Specific methods of molding thermosets are: Reactive injection moulding (used for objects such as milk bottle crates) Extrusion molding (used for making pipes, threads of fabric and insulation for electrical cables) Compression molding (used to shape SMC and BMC thermosetting plastics) Spin casting (used for producing fishing lures and jigs, gaming miniatures, figurines, emblems as well as production and replacement parts)

Properties

Thermosetting plastics are generally stronger than thermoplastic materials due to the three-dimensional network of bonds (crosslinking), and are also better suited to high-temperature applications up to the decomposition temperature since they keep their shape as strong covalent bonds between polymer chains cannot be easily broken. The higher the crosslink density and aromatic content of a thermoset polymer, the higher the resistance to heat degradation and chemical attack. Mechanical strength and hardness also improve with crosslink density, although at the expense of brittleness. Fiber-reinforced composites

When compounded with fibers thermosetting resins form fiber-reinforced polymer composites, which are used in the fabrication of factory finished structural composite OEM or replacement parts and as site-applied, cured and finished composite repair and protection materials. When used as the binder for aggregates and other solid fillers they form particulate-reinforced polymer composites, which are used for factory-applied protective coating or component manufacture, and for site-applied and cured construction, or maintenance, repair and overhaul (MRO) purposes.

Examples

Polyester resin fiberglass systems: sheet molding compounds and bulk molding compounds; filament winding; wet lay-up lamination; repair compounds and protective coatings. Polyurethanes: insulating foams, mattresses, coatings, adhesives, car parts, paint rollers, shoe soles, flooring, synthetic fibers, etc. Polyurethane polymers are formed by combining two bi- or higher functional monomers/oligomers.

Polyurea/polyurethane hybrids used for abrasion-resistant waterproofing coatings. Vulcanized rubber. Bakelite, a phenol-formaldehyde resin used in electrical insulators and plasticware. Duroplast, light but strong material, similar to Bakelite used for making car parts. The urea-formaldehyde foam used in plywood, particleboard, and medium-density fiberboard. Melamine resin used on worktop surfaces. Diallyl-phthalate (DAP) used in high temperature and mil-spec electrical connectors and other components.

Usually glass filled. The epoxy resin used as the matrix component in many fiber-reinforced plastics such as glass-reinforced plastic and graphite-reinforced plastic; casting; electronics encapsulation; construction; protective coatings; adhesives; sealing and joining. Epoxy novolac resins used for printed circuit boards, electrical encapsulation, adhesives, and coatings for metal. Benzoxazines used alone or hybridized with epoxy and phenolic resins, for structural prepregs, liquid molding, and film adhesives for composite construction, bonding, and repair.

Polyimides and Bismaleimides used in printed circuit boards and in body parts of modern aircraft, aerospace composite structures, as a coating material, and for glass-reinforced pipes. Cyanate esters or polycyanurates for electronics applications with the need for dielectric properties and high glass temperature requirements in aerospace structural composite components. Mold or mold runners (the black plastic part in integrated circuits or semiconductors). Furan resins used in the manufacture of sustainable bio-composite construction, cement, adhesives, coatings, and casting/foundry resins. Silicone resins used for thermoset polymer matrix composites and as ceramic matrix composite precursors. Vinyl ester resins used for wet lay-up laminating, molding, and fast setting industrial protection and repair materials.