PVC COMPOUNDING & PROCESSING:

POLYVINYL CHLORIDE:

PVC is a product based on two of the earth’s natural resources, salt and oil. Salt water electrolysis yields chlorine (in addition to caustic soda and hydrogen). Ethylene can be derived from naphtha when oil is refined. Chlorine and ethylene can be combined to form the monomer, vinyl chloride (VCM). PVC results from the polymerization of vinyl chloride (PVC COMPOUNDING & PROCESSING).

(PVC CHEMICAL CONFIGURATION)

PVC cannot be processed on its own due to its very low thermal stability and high melt viscosity. Therefore, it is necessary to combine with the polymer a number of suitable additives to give a wide and varied range of properties to satisfy many different end-use applications. It is this scope for generating a wide range of properties through appropriate formulation that gives PVC a broad application coverage that is unmatched by any other commodity thermoplastic. Its durability (85% is used in medium- to long-term life span applications), linked to its cost-effectiveness, has made it the second largest commodity plastic after polyethylene.

PVC COMPOUNDS:

PVC compounds are based on the combination of the polymer and additives that give the formulation

necessary for the end-user. The convention in recording the additive concentration is based on parts per hundred of the PVC resin (phr). The compound is generated by intimately mixing together the ingredients, which is subsequently converted into the gelled article under the influence of heat (and shear). Depending on the type of PVC and additives, the compound prior to gelation can be a free-flowing powder (known as a dry blend) or a liquid in the form of a paste or solution.

PVC compounds can be formulated, using plasticizers, into flexible materials, usually called PVC-P.

Compounds without plasticizer for rigid applications are designated PVC-U.

HOMOPOLYMERS:

The VCM repeat unit is linked in a head-to-tail fashion and the number of repeat units can range between 500 and 1,500. This corresponds to a theoretical molecular weight range of approximately 30,000 to 95,000. The properties of PVC are influenced by its average molecular weight and its molecular weight distribution. The chemical structure deviates from the theoretical chain with chain branching occurring during polymerization.

Commercial PVC polymers are essentially amorphous but also have a crystalline phase amounting to

approximately 10% and a two-dimensionally ordered hematic phase depending on processing history.

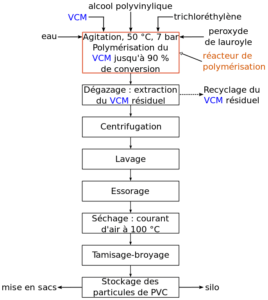

monomer droplets can agglomerate to a greater or lesser extent in the course of the polymerization. The reaction can be chemically short-stopped when the desired conversion has been reached by the use of particular phenolics. The suspended droplets of liquid monomer are progressively converted to solid or porous PVC particles. Unreacted VCM is stripped from the polymer and water is separated by centrifuging. The polymer is then dried, typically in fluidized bed drying equipment. Prior to start-up of the next polymerization cycle, the reactor is cleaned and coated with an antifouling agent.

Typical suspension polymerized PVC has a mean particle size of 100-150 µm with a range of 50-250 µm. The particles are complex and irregular in shape with a dense semipermeable skin.

S-PVC is the most common type of resin (around 85% of total PVC produced) used in both rigid and flexible applications and grades are formulated to meet an extensive range of requirements such as, high plasticizer absorption for flexible products, or high bulk density and good powder flow required for rigid extrusion.

(S-PVC MANUFACTURING PROCESS)

Chlorinated PVC (CPVC)

CPVC is manufactured by chlorination of PVC polymer thereby raising the chlorine content from 56% to around 66%. Chlorination takes place primarily at the -CH2- groups along the polymer chain so that the resulting structure becomes virtually a copolymer of vinyl chloride with 1,2 dichloroethylene.

Chlorination of PVC reduces the forces of attraction between the molecular chains. CPVC is also essentially amorphous. Both of these factors allow CPVC to be stretched more easily and to a greater extent than PVC above its glass transition temperature. CPVC has a glass transition temperature approximately 50% higher than PVC but also has a higher melt viscosity in processing. The upper service temperature for CPVC is approximately 100 °C in comparison to PVC at 60 °C.

Pipe, moldings and sheet are formulated for high-temperature use based on CPVC or blends of

CPVC and PVC.

PVC Resin Characterisation:

Molecular Weight:

PVC resins are polymerized to different molecular weights to suit the particular processing technique and end-use application requirements. The resin contains a random distribution of molecular weights and number average, weight average and molecular weight distribution can be measured. Normally, however, for production control, the dilute solution viscosity of the resin is used and the molecular weight can be calculated from the Mark-Houwink equation expressed in terms of K value or viscosity number. Commercially available PVC grades are supplied in K values ranging from 57-80.

Particle Size

Various techniques are utilized to measure the particle size range. Sieving is the most common technique,

particularly for suspension resins, and can be used to measure particles above 30 microns. For particle sizes below 100 microns, techniques such as sedimentation, optical and electrical sensing can be used.

Bulk Powder Properties

Bulk density and packed bulk (or tapped) density are important properties. The bulk density determines the weight of resin that can be stored in a vessel and the amount a mixer can hold. It also has a major influence on extruder output rates. The bulk density of a resin depends upon its porosity, particle shape, and particle size distribution. For suspension resin, bulk density is typically in the range of 450-650 kgm-3.

The packed density is based on the ability of the resin to occupy the smallest space without physical distortion and is usually 10-30% greater than the bulk density. Another important consideration is powder flow time as it governs the speed and ease of polymer discharge from a silo or from a mixer. This is influenced by the PVC particle shape, size distribution and compound formulation ingredients.

Key Additives

PVC formulations can include many different types of additives which assist in imparting a large range of physical and chemical characteristics. This versatility is the main reason why PVC has been so successful as a commodity thermoplastic, from medical applications such as tubing and blood bags to long life applications such as window frames and rainwater goods. The unique polar characteristics of PVC permit a wide range of appropriate additives to be incorporated within the polymer. The main groups of additives are:

Heat stabilizer, Plasticiser, Impact modifier, Process aid, Lubricant, Filler, Flame retardant/smoke Suppressant, Pigment, Blowing agent, Biocide, Viscosity modifier, Antistatic agent, UV absorber, Antifogging agent, Bonding Agent

Processing Techniques

Prior to processing, it is necessary for the PVC and formulation additives to be combined intimately

together in some form of the mixer. The main converting processes are:

• extrusion

• calendaring

• injection molding

• extrusion/stretch blow molding

• spreading/coating

• rotational molding

• dip molding

• slush molding

PVC RESIN PRODUCERS IN GLOBAL MARKET:

- Shin-Etsu

- FPC-Formosa

- Geon

- Solvay

- EVC

- Kondea Vista

- Atofina

- Borden

- Norsk Hydro & many more..

Global Market Usage Analysis:

| Pipes/Fittings | 36% |

| Profiles | 13% |

| Rigid Film/Sheet | 7% |

| Flexible film/Sheet | 7% |

| Wire & Cable | 7% |

| Flexible Profile/Tubes | 5% |

| Flooring | 3% |

| Coatings | 2% |

| Bottles | 3% |

| Others | 13% |

PLASTICIZERS:

PHTHALATES;

regarding the possible negative impact of phthalates on the environment and human health due to alleged carcinogenic, endocrine modulating and reproductive effects. In particular, their use in toys, healthcare products and flooring has raised much debate and analysis at various levels concerning migration, blood compatibility.

The main phthalates under investigation are butyl benzyl phthalate (BBP), dibutyl phthalate (DBP),

di-2-ethyl hexyl phthalate (DEHP), diisononyl phthalate (DINP) and diisodecyl phthalate (DIDP).

These investigations include EU risk assessments based on sound science but the political positions on flexible PVC and phthalates cannot be ignored.

Adipates

PVC food packaging film (cling film) has been used for a number of years for wrapping fresh meat; for food storage, and for protecting food in the home. The most common plasticizer used in this application is-2-Ethylhexyl adipate (DEHA), in combination with polymeric plasticizers and epoxidized soya bean oil.DEHA is used in preference to phthalates due to improved flexibility at lower temperatures and also gives the necessary permeability to oxygen and water vapor to preserve the freshness of the food.

Heat Stabilisers

Lead-Based Stabilisers

Primarily used extensively for PVC-U applications in Europe and the Far East viz. pipe, fittings, and profile, lead stabilizers have been very cost effective heat stabilizers. For similar reasons, plus good insulation resistance, lead stabilizers have also been used in PVC-Pin wire and cable across the world. Their toxicity hazards have been well known and controlled, particularly in relation to worker exposure.

Bisphenol A/Alkylphenols

Bisphenol A has been used as an inhibitor at the PVCpolymerisation stage and as an antioxidant. There has been some concern regarding possible health hazards and its use has been voluntarily stopped or restricted to levels that do not exceed the predicted any effect concentration in waste water etc. The content of Bisphenol A in, and its migration from PVC film, has been determined by high-performance liquid chromatography (HPLC).

Epoxidised Soya Bean Oil (ESBO)

ESBO is a heat stabilizer and secondary plasticizer used in PVC-P applications. It has food contact approval up to certain limits but there have been some environmental/political issues concerning the possible use of genetically modified soya bean oil in the manufacture of ESBO. The migration of ESBO from PVC-P used in gaskets for sealing baby food jars has been examined.

Solid Stabilisers

Lead Composition:

Lead compounds, usually based on a mixture of lead salts, e.g., tribasic lead sulfate or dibasic lead phosphite, and lead soaps, e.g., dibasic or normal lead stearates, have been very cost effective heat stabilizers for many years, and function as HCl absorbers. They are particularly suitable for wire and cable electrical insulation because of their complete nonconductivity and the inert nature of the chloride formed with HCl.

Technical limitations to their use have been opacity and sulfur staining. Their cumulative toxicity has been mainly a concern for worker exposure. Apart from wire and cable, their use has been restricted to PVC-Applications in Europe and Asia.

Non/low dusting products, which include the lead components in a safe handling state, in combination

with lubricants (one-pack), have been available for many years in different product forms – flake, granule, tablet, and dosage packs. These one-packs are tailored to suit the processing technique, primarily extrusion and injection molding, and end-use specification.

Calcium Zinc (Ca Zn) Based:

One of the most successful developments in recent years has been the progress made in solid Ca Zn

stabilizer formulations to replace lead on a cost-effective basis.Ca Zn formulations are a complex blend of calcium and zinc soaps together with acid acceptors and organic-stabilizers. Efforts have been made to increase the acid absorption capability in these systems.

The role of the co-stabilizer is also critical in maintaining initial color and early color hold on processing. Alternative calcium carboxylates have also been evaluated. Various Ca Zn systems are now available for the pipe. fittings, profile and wire, and cable, from suppliers such as Baerlocher and Clemson. Solid Ca Zn systems have also been developed for PVC-P applications as replacements for liquid Ba Zn stabilizers where volatility and emissions may be an issue. Non-dusting product forms have also been developed, due to the light and fluffy nature of the Ca Znsoaps (stearates).

Liquid Stabilisers

Organotin Compounds:

Organotin compounds are primarily based on alkyl tin such as methyl, butyl or octyl derivatives, usual mixtures of di-alkyl and mono-alkyl. They can be further classified as mercaptides or carboxylates based on different carboxylic acids. The main features of tin stabilizers are good initial and long-term color hold coupled with excellent clarity, linked to their good compatibility. The most powerful compounds are the thioglycolate ester derivatives and these are the most common. The octyl versions are approved (up to a maximum level) for use in rigid food contact and medical applications. Sulfur-free maleate based tins impart excellent light stability to clear PVC used in outdoor applications but require particular lubrication systems due to their anti-lubricating effect. Limitations to their use include their relatively high cost and unpleasant odor (particularly for the sulfur tins) and their use is now almost exclusively in PVC-U applications. The performance of organotin mercaptides is not only based on the amount of tin metal content but on the organotin species, mercaptide ligand chemistry and organic co-stabilizer. The mechanism of organothiotin stabilization has been studied extensively.

Mixed Metal Compound:

Liquid mixed metal heat stabilizers are a blend of the metal soaps or salts in combination with organic phosphites and co-stabilizers in a liquid medium. These materials are used almost exclusively in PVC-P applications.

Barium Cadmium (Ba Cd)

Barium cadmium based systems (may also include zinc)have been available for many years due to their cost-effectiveness in combination with good initial color and long-term stability. However, in the European area, their use was voluntarily phased out by the PVC industry in 2001, due to severe restrictions for environmental and toxicity reasons concerning cadmium. Cadmium-based stabilizers are still used in the USA and Asia Pacific areas but are coming under increasing health and environmental scrutiny.

Barium Zinc (Ba Zn)

Ba Zn based systems now have the majority market share for stabilization of PVC-P in Europe due to extensive formulation development based on increasing the barium content and the important role of new and existing organic co-stabilizers. Suppliers include Akros. One issue with liquid stabilizers is the emission of volatile components (phenol from the organic phosphite, solvent, etc.) during processing and from the end use application, e.g., floor and wall coverings. Analytical techniques are now available to detect volatile organic compounds (VOCs) and so influence stabilizer development. New organic phosphite-zinc technology has also been introduced to improve this characteristic.

Calcium Zinc (Ca Zn)

Calcium Zinc (Ca Zn)Traditionally less effective as a heat stabilizer, much work has been carried out to develop more sophisticated and higher efficiency heat stabilizers based on Ca Zn. This is based on the ‘concerns’ about barium as a heavy metal although there is no evidence of health or environmental concerns. In addition to further formulation development, complex polyphosphates, new Ca Zn intermediates and new calcium technology have all been promoted.

Potassium Zinc (K Zn)

K Zn stabilizer/kickers are used primarily to activate the decomposition of blowing agents(azodicarbonamides) for PVC foam. (An alternative approach has been the development of modified azodicarbonamides incorporating an activator system.

Plasticizers:

Plasticizers are added to PVC to achieve flexibility and workability. The flexibility or softness is determined by the type of plasticizer and level used in relation to the PVC (phr). They also operate as an internal lubricant between the PVC molecules. Based on organic esters,e.g., phthalates, adipates, trimellitates, phosphates, etc., addition levels can be as low as 20 phr for semi-rigid to100 phr for very flexible applications. The effect on thermal stability significantly depends on the physical state of the PVC-plasticiser system (260). The relative amount of crystalline PVC in VC/diethylhexyl phthalate has been identified on the basis of a combination of carbon-13 solution and solid-state nuclear magnetic resonance (NMR). The main factors which influence plasticizer choice are determined by the specification requirement of the finished product and depend on:

• Formulation cost

• Migration/permanence

• Plasticisation effect

• Solvating efficiency of the plasticizer for PVC predicted using Hansen solubility parameters and the Hildebrand solubility parameter

- Volatility

- Plastisol viscosity

- Extraction

The most commonly used plasticizers, together with their characteristics, are listed in Table 3.

The fundamentals of plasticizer selection have been listed. The thermodynamics of mixing PVC with phthalate esters have been studied. PVC-plasticiser interaction has been described using light transmission. The volatile photodegradation products from modelplasticised (dibutyl adipate – DBA) and titanium dioxide (TiO2 ) pigmented films have been determined with CO2 being the main constituent.

The ease with which plasticizer is combined with PVCis a measure of processing characteristics critical in the dry blend mixing operation of S-PVC or the gelation stage of plastisols. Predictive equations have been developed.

For high-temperature performance linked to low migration and volatility, trimellitates are used, Plasticisers based on pyromellitic tetraesters have also been proposed, Analytical methods have been developed to dentifymonomeric plasticizers in flexible PVC, PVC-P materials, subjected to aging under the model and climatic conditions, have been extensively tested. Properties are lost as a result of diffusion controlled adsorption of the plasticizer and mathematical description of the aging process has been formulated to predict lifetime. Plasticizer loss on aging has also been identified in the spectroscopic investigation of roof membranes in service for a varying number of years, Stain resistance of resilient sheet flooring has been related to the plasticizer, wear layer toughness and thermoplastic nature.

The plasticizer structure, level, extraction resistance, volatility and solubility all have an influence, The phenomenon of plasticizer migration into polyurethane foam, leading to hardening and cracking in arm and headrest applications, has been investigated and a mechanism proposed.

SOP FULL FORM

Phthalate Alternatives

Several alternatives to phthalate esters have been promoted, primarily due to the considerable media,

legislative and scientific attention on phthalates. Most suggested alternatives already have a niche use in specific PVC-P applications.

A phenol alkyl sulfonate ester is claimed to replace DEHP. Benzoate esters have already been used for some time and new blends have been introduced for plastisols.

Di-isononyl-cyclohexane-1,2-dicarboxylic ester(DINCH) has also been developed, Citrate based plasticizers, although much more expensive, have particular use in medical and packaging films.

Table : 01 Plasticisers type & its applications:

| Plasticisers type | Characteristics | Typical Uses |

| Commodity Phthalate Esters | ||

| C8 Di-2-Ethylhexyl phthalate (DEHP)/Dioctyl phthalate (DOP) Di-isooctyl phthalate (DIOP) |

Good fusion rate & viscosity | General Purpose |

| C8 – C10 Di-isononyl phthalate (DINP) Di-isodecyl phthalate (DIDP) |

Slightly less efficient but lower volatility than C8 | Toys & general purpose with good low-temperature performance |

| C7 Di-isoheptyl phthalate (DIHP) Dipropylheptyl phthalate (DPHP) |

Good Solvation | Flooring/Coating Plastisol cable |

| C13 Di-isotridecyl phthalate (DTDP) |

High gelation temp. Low extraction, Good migration resistance | High-temperature cable insulation |

| Speciality Phthalate Esters | ||

| <C8 Dibutyl phthalate (DBP) Di-isobutyl phthalate (DIBP) Butylbenzyl phthalate (BBP) |

Fast fusing, high volatility, Lower Plasticising efficiency | Flooring |

| Phosphate Esters | ||

| Triaryl phosphates Isobutylated or isopropylated triaryl phosphate esters |

Flame retardant with excellent performance | Electrical cable & general applications, like tents, covers & belts etc. |

| Trimellitate Esters | ||

| Tris-2-ethylhexyl trimellitate/Tri octyl trimellitate (TOTM) Trimellitate ester of mixed semi linear C7 and C9 alcohols (L79TM) Trimellitate ester of mixed C8 and C10 linear alcohols (L810TM) |

Better extraction and migration resistance. Good high temperature, but poorer low temperature performance. |

High specification electrical cable insulation and sheathing. Automotive interior (low fogging). |

| Secondary Plasticisers | ||

| Chlorinated Paraffin | Hydrocarbons chlorinated to level of 40-50%. Have some compatibility constraints and can influence heat stability |

Used in conjunction with primary plasticizers for volume with cost cutting,

Chlorine is help for fire retardancy |

| Epoxidised soybean oil (ESBO) Epoxidised linseed oil (ELO) |

Primary use as a secondary heat stabiliser but also impart flexibility. Compatible only at relatively low addition levels. |

General Use |

| Polymeric Plasticisers | ||

| Polymeric adipates of differing molecular weight. Polyphthalates |

More difficult to process/less compatible but excellent resistance to extraction. High cost. |

Application requiring excellence performance and chemical resistance |

Process Aids

Process aids are added primarily to uPVC to improve fusion characteristics and melt flow during the processing stage. Addition levels are typically from 1-6 phr with resultant improvements in output and surface finish. Transparency can also be improved in clear formulations. Chemically, these products are high molecular weight methyl methacrylate and alkyl acrylate copolymers.

The role that acrylic processing aids play in compound processability, end product properties, and manufacturing efficiency has been improved. Acrylic process aids are also playing a role in stabilizing factor as a co-stabilizer.

Impact Modifiers

Unmodified uPVC has relatively poor impact strength at, and below, ambient temperatures and the inclusion of an impact modifier significantly improves its performance. Examples of the different generic types of impact modifier that can be added to PVC formulations are as follows:

- methyl methacrylate-butadiene-styrene terpolymer(MBS)

• acrylate-polymethacrylate copolymer (acrylic)

• chlorinated polyethylene (CPE)

• acrylonitrile-butadiene-styrene terpolymer (ABS).

Addition levels are typically from 5-12 phr and their incorporation can influence gelation and melt viscosity. Having limited compatibility with PVC, it is believed that the impact improvement is achieved via the interruption of the homogeneous morphology into a heterogeneous structure. A dispersed phase in the PVC matrix is formed, which creates blockages to crack propagation and acts as an internal energy absorber.

Acrylic modifiers have good processing characteristics linked to reduced die swell and good outdoor weathering stability. Their use in window profile and siding applications are well documented.

CPE impact modifiers contain around 35% of chlorine and are thermoplastic in nature. With a similar melting point to PVC, they initially form a network structure which changes to a particulate structure on processing. They also have good processability and excellent weathering performance; consequently, they are also used for window profiles.

MBS impact modifiers are used in a wide range of applications, particularly for clear packaging, as their refractive indices are similar between PVC and the modifier. They are not suitable for outdoor applications.Their impact behaviour has been studied in terms of the ductile/brittle transition.

ABS terpolymer modifiers also process wellin clear applications giving low crease whitening and excellent chemical resistance. The heat distortion temperature of the ABS modified compound can be higher in comparison to MBS modified. They are also not suitable for outdoor applications.

Polybutene has also been shown to improve impact resistance and dynamic thermal stability in impact modified PVC-U formulations.

Heat Distortion Temperature Modification

A major disadvantage of PVC is its relatively low service temperature (60-70 °C) and the addition of high levels of some polymers can improve the heat distortion temperature and Vicat softening point. An example of such a polymer is alphamethyl styrene-acrylonitrile(AMSAN) copolymer. AMSAN-ABS polymer can be used as a combined heat and impact modifier.

Modifiers for Semi-Rigid and Plasticised Applications

CPE modifiers are also suitable for flexible PVC applications where a high degree of flexibility combined with durability is required. Acting as a permanent plasticizer, the liquid plasticizer component can be eliminated or substantially reduced.

ABS resins can be added to semi-rigid PVC formulations to improve hot melt strength, elongation, and low-temperature flexibility.

Lubricants

Lubricants function classically in two ways,(1) externally to reduce friction between the polymer melt and hot metal surfaces during processing, and (2) internally to reduce frictional forces within the polymer matrix and, in so doing, lower the effective viscosity. External lubricants, by definition, have poor compatibility with PVC. Internal lubricants are more compatible and have high polarity. Both types are essential for processing of PVC-U formulations. In practice, most lubricants have both external and internal characteristics, but vary in the ratio of one to the other in the way they perform. However, the correct balance and type of internal to external and addition level are crucial due to the influence on gelation level, plate-out of incompatible materials in the die and calibration equipment, and physical properties.

Typical strongly external lubricants are paraffin wax,polyethylene wax, oxidised polyethylene wax, and stearic acid. Typical strongly internal lubricants are glycerol esters and fatty acids. Calcium stearate functions somewhere between internal and external, depending on addition level. It also acts as an acid scavenger.

Fillers

For most PVC-U and PVC-P applications, fillers are added primarily to reduce formulation cost, but some are also used to enhance properties and performance. There is a balance between the cost benefits and any acceptable deterioration in physical properties that could result. The density of the final product will increase, of course, at higher filler levels. Another important aspect is the influence on processing with respect to output, plate-out and surface finish.

Calcium Carbonate

Calcium carbonate (also known as chalk) is the most commonly used filler for PVC. This material is mined as calcite mineral and ground to a particular particle size range. It may also be precipitated from solution to give a fine particle size suitable for use in high performance areas.Particle size is important and, for some applications

requiring good weathering and impact performance(window profile), the ultra-fine milled, high whiteness,natural version is normally used.

To ease dispersion, the filler is usually coated with stearic acid. Coat ultrafine and precipitated calcium carbonates are claimed also to have a positive effect on impact properties in impact-modified formulations. The abrasive wear of calcium carbonate, on melt processing equipment, is not significant but increases with increasing levels.

Tensile strength properties of PVC-U, filled with precipitated and ground calcium carbonate, have been investigated.Calcium carbonate nano particles are commercially available and are claimed to give a cost effective way of increasing impact strength. Their use in impact modified PVC has improved mechanical properties.

Wood Fillers/Fibres/Flour Composites

The use of wood fillers has expanded considerably, particularly in the USA. In comparison with traditional products, wood-filled PVC has superior weathering resistance and can be used as wood. Finite element analysis, of impact durability, has been carried out to establish the optimum profile wall thickness to resist impact for PVC containing 60% wood fiber. The positive effects of modifiers on physical properties have been identified.

The use of CPE as a compatibiliser, for composites containing 25% and 40% wood flour, has been demonstrated with improved melt strength and improved surface finish. Accelerated UV weathering performance testing indicated that wood flour is effective chromophores as they accelerated the degradation of the polymeric matrix. However, there was no deterioration in strength and stiffness properties.

Other Fillers

Depending on the geographical area, ground marble fillers, some with surface treatment, is used for PVC-U and PVC-P applications. Ground dolomite (calcium magnesium carbonate) and limestone fillers are also used.

Talc has been used in calendered PVC compounds to increase melt cohesion and modulus of the finished material.Cellulose fillers, with and without silane coupling agent treatment, have been investigated at various levels showing an increase in physical properties and viscosity. Silane coupling agents have also been used for inter facial enhancement of PVC-P/silica composites. Calcined kaolin clays can be used in footwear(improved abrasion resistance) and cable (improved insulation properties).

Calcium silicate mineral filler has been proposed as is placement for calcium carbonate in the primary insulation cable compound. Calcined calcium sulfate has been suggested to effectively replace calcium carbonate in cable insulation.

Kaolin has a use in plastisol formulations giving good rheological control. Calcium carbonate is also used in this area. An alternative to calcium carbonate, phyllite,has been evaluated. This material, which contain quartz, muscovite and kaolinite, was characterised on the basis of paste viscosity, gelation and fusion behaviour, and mechanical properties.

Flame Retardants (FR) and Smoke Suppressants (SS)

PVC-U formulations have low flammability due to the chlorine content. The addition of plasticiser in PVC-P formulations necessitates the use of flame retardant and smoke suppressant additives. These additives are known as functional fillers and a correct balance is necessary to achieve all the end-use specification requirements. They are predominately used in cable, conveyer belting and roofing membrane formulations to give resistance to fire initiation and propagation. It is also important to reduce dripping in a fire situation and that as little smoke as possible is generated. Antimony trioxide has been used extensively, usually in combination with phosphate ester plasticizers, giving excellent fire performance and mechanical properties.

The FR mechanism is activated by the formation of antimony oxychloride which acts as a radical scavenger and flame poison. However, antimony trioxide is a suspected carcinogen and work is ongoing to replace or reduce the levels used. The use of zinc sulfide has been suggested.

Zinc borate is also an effective SS in combination with phosphate ester plasticiser. The combination of ammonium octamolybdate and zinc stannate is also beneficial.

Ethylene copolymers (high molecular weight flexibilisers) have been proposed to replace liquid plasticiser for low smoke FR PVC cable formulations.

Calcium carbonate and lithium carbonate fillers also act as HCl absorbers and the effect on HCl generation during the combustion of PVC-P have been shown to be effective, particularly when used in combination.

Pigments

Pigments for PVC must be thermally and light stable,have good dispersibility and be compatible with in the formulation. Inorganic pigments are the most common type.Titanium dioxide (TiO2) pigments are used to give‘bright’ whiteness and opacity. Specific titanium dioxide grades are used in PVC-U applications and contribute to outdoor weathering performance. Their influence on photo degradation, and on the kinetics of weathering have been studied. Reversible discoloration effects linked to the photochemical degradation of titanium dioxide pigmented PVC, have been shown, after a period of storage of the aged material in the dark. This has been attributed to the formation of particular polyenic sequences, with the screening effect of the pigment protecting these polyenes against photo-oxidation, so permitting these polyenes to accumulate in the degraded polymer.

Volatile species produced during the UV irradiation of a white pigmented PVC construction panel have been measured as a function of irradiation time. Rates of volatilization of organic and chloro-organic compounds dropped sharply with irradiation time. This drop was attributed to the cross linking of the irradiated surface which became chlorine deficient in TiO2 pigment.

Pinking of PVC profiles, in mild climatic conditions, has been observed in service. This has been explained by the formation of polyene sequences not completely photo oxidatively bleached under conditions of oxygen starvation. One predictive test has been designed and validated. Other predictive tests have also been suggested. Titanium dioxides for use in PVC plastisols must satisfy the need for good wettability and dispersion within the liquid medium. Paste storage stability is also important.

The effects of different surface treatments on TiO2 on these parameters have been studied, with the conclusion that the amount and type of alumina treatment is significant.

Aluminosilicates, as pigment extenders to partially replace TiO2 in plastisols, have been investigated, with whiteness retention and reduction in surface gloss.

Lead chromate pigments, traditionally used for pipe and cable applications, are linked with the phase-out of lead-based stabilizers. Special pigment systems based on organic or organic/inorganic combinations are available.

Biocides

PVC-P materials, such as flooring and roofing material,can be prone to microbiological attack in humid or damp conditions. This is due to the fungi using the plasticizer at the surface of the article as a food source. This can lead to partial discoloration (pink color or black specks) which can further cause a tacky surface where dirt can accumulate. Unpleasant odors may also be a consequence.

Biocides function by becoming active on the surface of the material to destroy the fungi. Plasticizer transfer to the surface is limited by the process of diffusion of the plasticizer within the material, the fungus also acting as a leaching solvent.

Blowing Agents

Solid blowing agents are materials which decompose to release gases at particular temperatures matching the appropriate melt viscosity necessary to retain the foam structure. There are two main types:(1) azodicarbonamide, which is exothermic in nature and decomposes to give primarily nitrogen gas and(2) sodium bicarbonate, which is endothermic and so absorbs heat as it releases carbon dioxide gas. Various grades are available to suit particular applications and both have well-controlled particle size distribution. The azo compounds can be specially formulated, to include an activation agent which catalyzes the decomposition and so increases the total gas evolved. Granular forms improve handling.

PVC-U foams incorporate sodium bicarbonate and the results are available of an investigation into controlling the rate of gas evolution and heat of decomposition. The manufacture of cellular PVC/wood composites has been studied. The properties achieved, as foam density was reduced, were examined showing suitability form any wood replacement applications.

Antioxidants and Light Stabilisers

Primary antioxidants, such as hindered phenols, operate as effective radical scavengers to protect the PVC material during processing and in use (preventing photo degradation). Phosphites and thiosynergists are also used as secondary antioxidants to extend the efficiency of the primary antioxidant by reduction of oxidation intermediates. These can be added at very low levels at the polymerization stage and in combination with the stabilizing package at the blending stage.

Light stabilizers also prevent photo degradation. UV absorbers such as hydroxybenzophenone or

hydroxyphenyl triazole types operate by absorbing and dissipating UV radiation prior to potential degradation of the polymer.No permanent chemical change occurs, so activity is retained. Hindered amine light stabilisers (HALS) are also used but their activity is not particularly well understood.

Cyanoacrylates have been proposed as a new range of UV absorbers for PVC and other plastics.

Bonding Agents

PVC plastisol, spread on to industrial fabrics based on polyester or polyamide fibers, requires the addition of a chemical bonding agent to improve the inter facial adhesion. Based on polyisocyanurates, dispersed in a plasticizer, this functions by reacting with the polar groups in the synthetic fibre to give strong chemical bonding at the interface of the fabric and PVC. These materials are highly reactive and the plastisol formulation has to take this into account in relation to plastisol viscosity build-up

Compounding and Processing Technology

Compounding

The intimate mixing of the PVC resin with its associated additives is necessary prior to convert

into a thermoplastic melt.

Dry Blend Mixing:

High Intensity

Batch high speed mixing, followed by a cooling stage, is the most favored process to produce PVC-U and relevant PVC-P dry blends at high outputs. In addition to the formulation ingredients necessary for the particular application, other important criteria have also to be considered for the dry blend mixing stage and subsequent transportation to the processing equipment viz. homogeneity, free-flow ability, bulk density, ease of handling and storage.

High-intensity mixers are heated cylindrical tanks with the mixing tool (propellers or knives) mounted on a mixing shaft. Under the effect of transmitted and frictional heat, the temperature rises, allowing the absorption of the liquid and low melting solid components. Further mixing ensures that the non-melting components are efficiently dispersed (in some cases fillers and certain pigments are added prior to reaching the final mixing temperature). The hot mix(now around 110-130 °C) is transferred to a much larger, cooled, low intensity mixer and cooled to~50 °C. This results in the reduced agglomeration and improved free-flowing properties (by reducing electrostatic charges).

The process can be automated in relation to weighing of ingredients and spraying of liquid components into the mixture.

Low Intensity

Virtually shear-free, low-speed mixers offer gentle product handling with a uniform distribution of all ingredients, with no change in particle identity. The walls of the mixer carry the bulk material by friction producing continuous dividing and reuniting of the material. Centrifugal forces are sufficient to throw material particles into free space where they collide with other particles.

This breaks up agglomerates. Normally, this technique is used for cold mixing, but heating may be necessary to aid plasticizer absorption. There are several types of mixers: helical ribbon, ribbon bar or paddle mixers.

Melt Compounding

For certain operations or scale of operations, the dry blend is fed directly into the processing equipment, e.g.,pipe and profile extrusion, which obviously includes the melt compounding stage.For some processes or smaller scale operations, the dry blend (PVC-U or PVC-P) must be gelled/melt compounded, usually into a pellet or dice form. This may be necessary for the type of processing equipment used for shaping the material, e.g., calendering, or where a high degree of homogenisation is required to achieve the performance requirements of the final

product. Continuous melt compounding extruders are now the favored option either based on:

(1) Co-rotating twin screws with kneading elements.The barrel is in segments and the length is determined by the process needs, with the screws designed to include mixing, conveying, plasticizing and homogenising.

(2) Oscillating kneader extruder, based on a single helical screw blade which in addition to its rotary motion also makes a reciprocating axial movement.In one complete turn of the screw there is one forward and backward motion. Kneading teeth or pins are mounted on the barrel, which is hinged, and the material is sheared in the shear gap between these teeth and the screw flights. This technique is reputed to give maximum mixing performance with relatively low energy consumption.A twin screw feeder unit is used to dose dry blend into the compounder.

A discharge screw feeds the melt into a pelletizer unit, which is a multi-hole die plate through which the melt is forced into strands, cut by rotating knives and cooled. Details are available of a range of extruders developed for PVC compounds.

Liquid PVC Blending

Plastisol or paste PVC mixtures are dispersions of emulsion or emulsion/micro suspension PVC resins in plasticizers. Alternatively, organosols are based on the use of a lower boiling point liquid.

The types of mixers used are:

(1) High-speed dispersion vertical mixers which are fitted with a variable speed drive and a toothed disc at the end of the vertical shaft. This type suits the lower viscosity plastisols used in wall and floor coverings.

(2) Low-speed planetary mixers fitted with vertical trellis type paddles which rotate around the drive access in a circular motion around the mixing bowl. There may be a two stage mixing procedure used where all the solids are dispersed in part of the plasticiser. The remaining plasticizer is added at the second stage, there by improving plastisol mixing. This type of mixer requires longer mixing times but is suitable for high viscosity pastes with very little friction being developed in the process.

All mixers are usually enclosed and fitted with a vacuum deaeration facility, particularly necessary for

transparent top coat and foam formulations.

Processing: Extrusion

Twin Screw

Almost exclusively used for extrusion of PVC-U into pipe profile and sheet, extrusion equipment consists of a cylindrical barrel containing two close fittings,inter meshed, Archimedean screws. PVC dry blend is fed in via a hopper at the start of the screws and is conveyed forward, softened, sheared and finally gelled by rotation of the screws and the heat of the barrel. The resulting homogeneous viscous melt is forced through a heated die fitted to the exit end of the barrel. Thereafter the downstream equipment sizes or calibrates cools and pulls off the product which is also cut to desired lengths.

The heated screws rotate in opposite directions (counter rotating) to each other and perform three basic functions which are feeding, gelation and metering, with the screw flights designed accordingly. Venting is incorporated to remove entrapped air and volatiles. The barrel is temperature controlled, usually in different zones, along the length. The concept of twin screw extrusion is a short residence time in order to minimize thermal degradation, linked to high output. Screws are typically chromium plated and/or nitrided to protect against acid corrosion and abrasion.

Barrels are internally lined with various highly nitrided steels. The role of shear stress, in PVC degradation, has been examined during extrusion and suggestions made in the modification of the flow channel to prevent polymer degradation. Two main types of screw design are used, i.e., parallel and conical and these have been compared.

Further information is available. The use of conical twin screw extruders for the extrusion of wood filled PVC has also been presented. The characterization of apparent viscosity for PVC wood fiber extrusion has been carried out and quadratic models used to establish tolerances with in which the dimensional and physical specifications were achieved.

Statistical analysis has been used to establish the optimum screw design for PVC extrusion with the capability of reducing extrusion temperature and decreasing slip velocity to reduce abrasion. The screw design is complex but enables melt temperature(which can be in the region of 190-200 °C) to be controlled more accurately. Screws are categorized by the ratio of their length to depth (L/D ratio) and have been 22/1 (22D) and 26/1 (26D). New 36D extruders have been introduced for higher output in combination with less wear. The positive influence of PVC grain morphology on extrusion performance has been studied.

Statistics, as a monitoring tool, can be used to determine if the process is under control. This has been positively identified in relation to the mean and standard deviation of the melt pressure and motor load. The processing window for PVC-U compounds should not be too restricting to allow for the batch to batch variations in formulation ingredients and minor temperature fluctuations.

A processing window contour mapping program, using sequential simplex techniques, has been used to evaluate the effects of formulation changes on PVC-U compounds. This is combined with the formulation cost to give an overall responsibility for the simplex to optimize. An optimum processing window can also be defined by the use of statistical experimental design. The effects of formulation variables on PVC-U processing and physical properties have been modeled.

The influence of processing variables on profile gloss has shown a direct relationship between gloss and surface roughness.

Single Screw

Single screw extruders develop more frictional heat and rely more on back pressure from the die to improve homogeneity. Screw design involves higher compression ratios, e.g., 2:1, which means the volume occupied between two fights at the start of the screw is twice that occupied between two consecutive flights at the end of the screw.PVC-P applications, such as wire and cable, glazing strip, profile, tubing, hose, etc., run on single screw extruders, are fed by the gelled compound. The melting behavior of various PVC compounds has been studied in single screw extruders and conclusions made in relation to the dominant driving force conveying the melt and melting mechanisms. The relationship between the physical properties of PVC-P profile extrusions and extrusion melt temperature has been investigated, showing an optimum level of temperature to achieve satisfactory physical properties and surface gloss. Flow instability of PVC-P, in a capillary extrusion, has been correlated with the long-time relaxation ascribed to generation and growth of PVC crystallites.

The shear rate in passing through a copper wire coating die has been determined as higher than one million reciprocal seconds when studied using capillary rheometry.

Downstream Equipment

Die design is critical to the extrusion process, material rheology and flow through the die. Once ascertained on a trial and error basis, it is now coming under more scientific investigation. An instrumented dual slit die rheometer, mounted on a twin screw extruder, has been developed to determine shear viscosity and slip velocity covering PVC formulations exhibiting very different flow behavior.

The simulation of profile dies, using finite element methods, has been demonstrated showing advantages in reduced sensitivity to output rates, temperatures, and material properties. A nonisothermal network flow model has been developed(this includes flow balancing, sidewall effects and dimensional changes that occur after dying exit), which gave good results. Computer-aided engineering software has been used to investigate modifications to the design of a PVC sewer pipe extrusion die resulting in improved output and product quality with modest changes.

For flat die extrusion of the sheet, critical variables are temperature control, residence time and flow channel streamlining. Recent developments have been presented. Sheet and film extrusion lines include cooling and polishing rolls. An overall review of extrusion tooling has been made covering twin strand extrusion, cost-effective tooling, flow, and cooling simulation and melt homogenization.

Profile forming is achieved by passing the extrude through a series of calibration dies, which cool the material through contact with the metallic walls of the calibrators. Vacuum holes or slots are used with the water cooled walls to improve and maintain final product dimensions. Alternatively, for pipe extrudate, the material is sized and subsequently cooled with water by total immersion or spray. The influence of different cooling environments, using a differential equation for heat transfer, has shown a direct relationship between the temperature profile during cooling and deformation. The bowing of PVC-U extrusions caused by differential thermal shrinkage, associated with different cooling rates, has been modeled.

Heat reversion effects, in PVC-U profiles, have been identified as a multi-axial parameter with the magnitude shown to be a complex function of a number of interrelated variables. Higher line speeds, without increasing reversion levels, are possible by allowing for die swell.

Injection Moulding

Injection molding is a discontinuous process that produces articles in the final shape. A mobile reciprocating screw gels, transports and forces material through a nozzle and into a mold. The relatively high melt viscosity and thermal stability of PVC require close attention in relation to temperature and shear conditions. The most important stages of the process are melted preparation and mold filling to minimize shear heating caused by excessive back pressure, screw speed or injection rate.

Screw and mold designs have made big advances. PVC-U applications, usually based on lower molecular weight polymer, cover the construction and telecommunication areas. The formulation and performance criteria have been evaluated for vinyl molding compounds. PVC-P applications include footwear, automotive, medical and electrical.

Strains imposed on the material during an injection can result in undesirable shrinkage and are indicative of the temperature at which the strains are imposed. A mathematical model has been developed to provide the basis for the interpretation of shrinkage data. A distribution map of the various relative temperatures attained during injection has been determined. Using time-resolved fluorescence has enabled the estimation of residual stresses on the skin layer of PVC moldings. To reduce the number of surface defects on PVC pipe fittings, the influence of injection molding conditions was studied experimentally and by finite element analysis, allowing optimization of the processing conditions.

Calendering

Early PVC calenders were modified from those used in the rubber industry. Calendering processes and machinery for rubber and PVC products have been examined.

A calendar is essentially a set of four giant steel rollers mounted in a cast iron frame, usually in an inverted L-shape, in such a way that they can be rotated, and the distance between each pair of rollers adjusted. Consecutive rolls squeeze the material resulting finally in a continuous sheet of the desired thickness. PVC, ranging from rigid to semi-rigid to flexible, is produced continuously in film or sheet up to approximate millimeters in thickness and up to and over2.0 meters in width. Calendering is much more capital intensive than the extrusion process, but higher production rates and more accurate product thickness are obtained. Mini calendars Calandrette® lines (from Battenfeld) are available for the production of rigid and semi-rigid PVC films with lower investment costs.

The calender rolls have to transmit heat evenly across the face and need to be independently variable in speed so that friction between two adjacent rolls can be applied. The surfaces of the rolls need to be contoured to an accuracy of a few microns to ensure even film thickness in both lengthwise and crosswise directions.

The surfaces of the final two rolls can also be textured, ranging from highly polished to heavy matt, depending on the sheet finish required. Hot melt is generated through a continuous extruder-compounder, e.g., feeding into the intake nip of the calendar. One alternative is an intensive internal mixer consisting of two heavy-duty teardrop shaped counter-rotating rotors in a heated chamber, based on a batch process, feeding onto a two-roll holding mill.

The passage of hot melt between the rolls creates a pressure forcing them apart and the calculation of

tolerances using a statistical model has been described. There is a rolling bank of feed material created

in the gap or ‘nip’ set between the first pair and also the second pair of rolls. Passage of the material is

controlled by roll temperature, surface finish and the ratio of the roll speeds at the nip. The final calender’s controls film thickness. The hot sheet is drawn from the final roll by stripper rollers which can be temperature controlled to permit gradual cooling, and regulated rotational to allow stretching to the required dimensions. In-line embossing can be carried out by feeding the hot sheet between a heated embosser and rubber backup role.

Final cooling is achieved using water-cooled drums. Plate-out can also be a problem in this area due to the formation of coatings which adversely influence sheet quality. The chemical structure of coatings, resulting from calendering of different feedstocks, has been analyzed and attempts made to establish the causes and mechanisms of coating formation.

Typical applications for PVC-P materials include floor and wall coverings, film packaging, decorative

Honestly, I don’t even know what a PVC mixer is until I came across this post. Now, I know that a PVC compound is based on the combination of a polymer and a bunch of additives. You talked about the PVC resin characterization and some of its components such as molecular weight and particle size. I guess each one has its purpose to be able to build an excellent product. I will definitely be reading more about the process of PVC mixing for better understanding. Thanks.

thanks for providing useful information on PVC COMPOUNDING & PROCESSING

need Information about PVC compounding handling & transfer

Need Information about PVC compounding Mixer.

Formulation cansultant of PVC compound, FR, FRLSH, pvc conduit, pipe, HDPE, Pvc Profile extrusion, NBR, TPE, Air Sole, EVA, PVC solvent cement, ZHFR, keychains.8979684240

Pls sir am delighted in your teaching

We need on how to make recycle pvc material shinny and grossing without breaking

Thanks

Mr ok collins

Good information about PVC material

Required Footwear Grade PVC Compound ingredients with quantity quality measures % tried & tested.

Required Extrusion (Granulating) unit 50kg to 100 kg per hour. Ready to work in partnership, royalty or onetime charge. +917507272167

need to know pvc compouding formulation for our PVC EDGE BAND new factory. how can you help us

Any experience using calcium carbonate bio polymer fiber filler from paper pulp in pvc compound?

sir you chemical configuration for PVC is CH2=CH-CL2. I Have confused you write only c2h2.

sir the chemical configuration for PVC is CH2=CH-CL2. I Have confused you write only c2h4.

Excellenmt items from you, man. I have be awware your stuff previous to aand you’re simply extremely

wonderful. I actually like what you’ve bought here,

really like what you are stating and the way in which wherein you say it.

You make it entertaining aand you still care for to keep it smart.

I can’t wait to learn much more from you. This is really a great site. https://odessaforum.Biz.ua