POLYPROPYLENE COMPOUNDING PROCESS

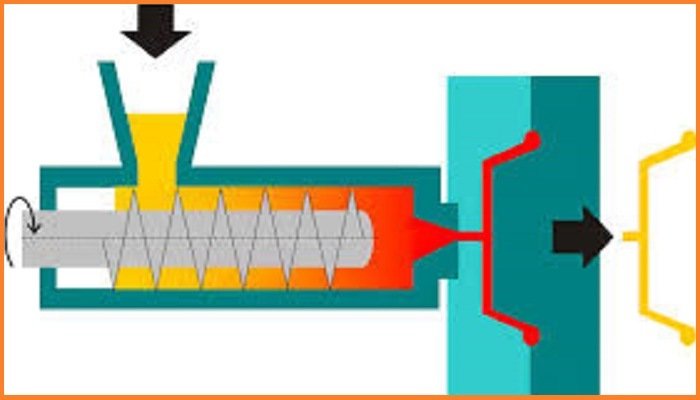

Compounding is defined as the process of incorporating additives, modifiers into PP for achieving uniformity on a scale appropriate to the quality of the articles subsequently made from the compound. It is also known as hot or melts blending.

Polypropylene (PP) sold for commercial consumption has some types of additive. We will define ‘unmodified’ PP as representing only those additives without which PP could not be viably processed in commercial extruders, molding machines and the like. Accordingly, we will define ‘modified’ PP as that which has additives designed to provide special environmental, processing or physical properties. Typical additives to unmodified PP include antacids such as calcium stearate, calcium pelargonate, zinc oxide or hydrocalcite. These compounds are required to neutralize catalyst residues that could otherwise form acids detrimental to the converter’s equipment. The second basic additive to PP is antioxidant. This is required, as a minimum to protect the polymer from chain scission during processing and ageing. Typical process stabilizer antioxidants are hindered phenols.

Most additional additives and modifiers such as clarifiers, flame retardants etc. are targeted to affect a certain class of properties. Further, fillers and reinforcements are incorporated to impart “Value Addition” to PP. High value added PP products can be made by “Modifying PP with elastomers such as EPM/EPDM.

Value added PP products

* Low-level additives

* Environmental Property Enhancement

In addition to process stabilizers, additional heat stabilizers are used to improve the long term heat ageing of PP. Several antioxidants will afford improvements, with the choice dependant on the environment requires. An important parameter is the continuous use temperature. Typical PP homopolymer with moderate stabilization has a continuous use temperature of 105 deg. c. Special stabilization can increase that temperature to 125 deg. C. Thioethers can act as long term heat stabilizers.

The UV resistance of unmodified PP is poor. However, stabilization can improve its performance significantly. Typically, hindered amines-can be used in combination with other appropriate additives to deliver service life or more than 5 years outdoors in both pigmented and non-pigmented products. This can be done without affecting the appearance of a component. In addition, if a black appearance is acceptable, special grades of carbon black at levels above 2% can provide a service life of more than 20 years.

In addition to the stabilized applications listed above, there are many specialized uses of PP that require low levels of stabilizers. Among the applications for these stabilizers are the protection of PP components in radiation sterilizing environments, the prevention of colour development in various environments and the stabilization of wire-coating resin against the effects of copper. Each of these unique applications requires specific additive packages.

Processing Property

Enhancements In addition to the need for application heat stabilizers, some manufacturing processes require exceptional melt stability. For example, if products will be reprocessed repeatedly, if high levels of scrap are used or if extruded sheet subsequently will be exposed to high temperatures, as in a thermoforming application, the goal would be to minimize degradation in the extrusion process.. In these cases, additional melt stabilizers are required. Phosphite-based products are used for this purpose.

In film resins, slip agents and antiblocks are added to improve the processing and performance characteristics of the film. Slip agents are typically amides, with the particular selection depending on the characteristics being sought. Typical antiblocks are utilized to prevent the film from sticking to itself, while slip agents are utilized to prevent the film from sticking to other surfaces, such as the converting equipment. Also used in film for processing and application performance are antistats. These products act to minimize static build-up as the film passes over the downstream equipment, as well as to minimize the dust pick up inherent in packaged products. For the latter applications, antistats are sometimes incorporated into PP used in sheets, bottles and moulded articles. Monoglycerides and/or diglycerides are typical PP antistats.

Injection moulding products may utilize additives to adjust processing performance in the form of lubricants and/or mould release additives. These additives may interfere with decorating.

Physical Property

Enhancements as a crystalline is responsible for many of the characteristics of PP, he ability to control it allows one to influence the physical properties of the resin. Nucleates are employed that provide sites for the initiation of crystals. The choice of nucleate will determine which properties are affected most significantly. The target properties are usually stiffness and heat deflection temperature, contact clarity and/or see-through clarity. Nucleators may also affect processing performance owing to their effect on the rate of polymer crystallization.

High Level additives (Fillers and Reinforcements for PP) W ith the exception of the carbon black at more than 2% level, all the additives mentioned in Section 2.1 are utilized at very low levels. Typically, the totals add level of these types of additives will remain below 2%. The properties that are most significantly affected by these type of additives are processing and environmental characteristics. TO achieve significant differences in properties, fillers and reinforcements are used at much higher levels. Fillers and reinforcements are generally distinguished by the resulting differences in properties that they provide to PP.

Fillers are defined as additives in solid form that differ from polymer matrix with respect to their composition and structure. They are generally inorganic in nature and less frequently organic and are used at levels of 10% and above. Different types of fillers can be classified as under: inert or Extender Fillers : These fillers occupy space in the polymer increase bulk density and lower cost and thereby extend the polymer. Active Fillers : These produce specific improvements in physical and/or mechanical properties. Reinforcements: These are specific type of active fillers. They increase tensile strength and flexural modulus of PP.

PP has the capability of accepting large amounts of mineral fillers (up to 70% by weight are marketed as master batches). These include various forms of cellulose, hydrated oxides, clay, glass, metal powder, carbon fiber, wollastonite, asbestos, talc calcium carbonate, mica and combinations of these. Each has certain characteristics that it.

Imparts to a PP compound and will be discussed in detail elsewhere. One of the original aims of introducing fillers was to decrease the cost of polymer by use of inexpensive fillers. However, it soon became apparent that improved properties were possible. This allowed use of high cost fillers, i.e. higher-purity, better color and special surface treatments to improve adhesion at the dispersed phase interface. The most important fillers for PP are calcium carbonate, talc and mica. Glass fiber is used to reinforce PP.

Therefore, the aim today in compounding fillers and reinforcements in PP is selective modification of properties for specified end-use or in other words “Tailor-Making” of properties. Selection criteria for fillers and reinforcements in PP when incorporating fillers and reinforcements into PP, a number of factors have to be considered. These are summarized below:

- Particle shape, mean particle size and particle size distribution of the fillers

- Dispensability and adhesion (linkage) with the PP matrix

- Abrasive action of the filler on the processing machines

- Properties of the filler/reinforcement such as specific gravity, intrinsic strength, inorganic impurities.

- Problems associated with dust when handling fine powders

- Cost of the filler/reinforcement

Reinforcement is justified only when a distinct improvement of properties/cost reduction compared to unreinforced PP is found or when a specific combination of properties is not achievable by other means:

Property Improvement

Surface Finish Improvement Calcium carbonate, talcs, Beeds.

Improve Tensile strength & Flexural Modulus Glass fiber, Carbon fiber & Wollastonite

Increased Conductivity Carbon Powder, Ni-coated mica, ss fiber

Can pp-ld-hm be mixed together to manufacture household items like ghamela and buckets. If yes tgen what shld be the ratio.

Yes..it could be and Ratio should be 85:10:05