PROCESS CONTROL & PROCESS PARAMETERS IN INJECTION MOLDING

PROCESS CONTROL-PROCESS PARAMETERS IN INJECTION MOLDING

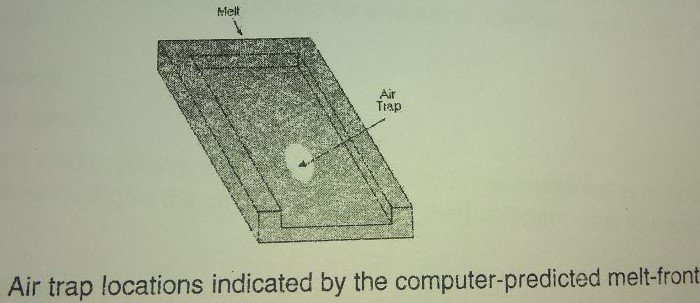

The injection molding cycle can be broken down in to 04 phase i.e Fill, Pack, Hold & Cooling/Plastication. The process begins with the mixing and melting of resin pellets....

THERMOPLASTIC MATERIAL & IT’S PROCESS

Thermoplastic material and It’s Process

PBT (Polybutaline phthalates):

Typical Application:

Household appliance (Example: food processor, blades, vacuum cleaner parts, fans, heir drier housing, coffee makers)

Electronics (Example: switches, motor housings, fuse cages, key caps for computer,...

MICROPROCESSOR CONTROL IN INJECTION MOLDING

MICRO PROCESSOR CONTROL: OPEN LOOP AND CLOSE LOOP

Why Micro processor required?

To ensure consistency of quality of injection moulded parts one has to look at the controls like pressure, speed, stroke & temperature. This is...

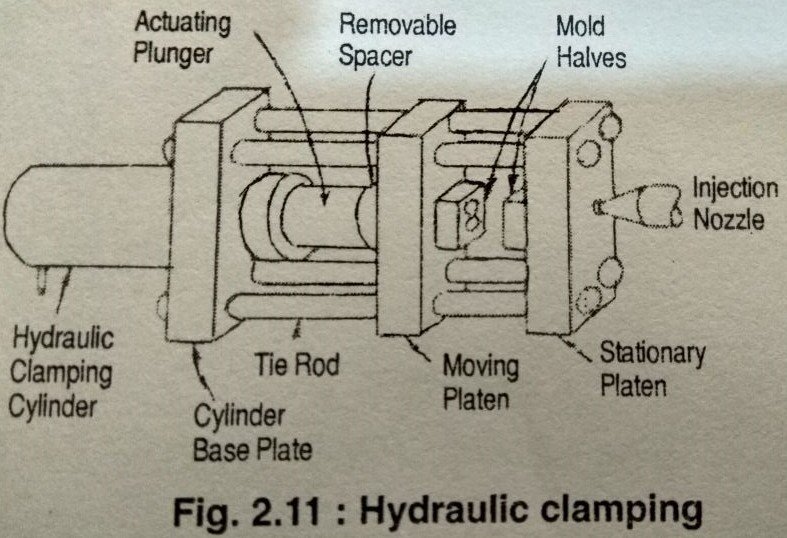

VARIOUS CLAMPING SYSTEM IN INJECTION MOULDING

CLAMPING SYSTEM: MANUAL, TOGGLE, HYDRAULIC, HYDRO-MECHANICAL & T BAR LESS CLAMPING

The function of clamping unite is to clamp the injection mould. The clamping pressure is set more there the injection pressure, so that the...

MATERIAL SELECTION FOR THE INJECTION MOLDING

MATERIAL SELECTION FOR THE INJECTION MOLDING

Material selection depends to a large extent on the functional constraints of the part. Both amorphous and crystalline thermoplastic resins are used in injection molding. Short glass fibers are...