Nylon

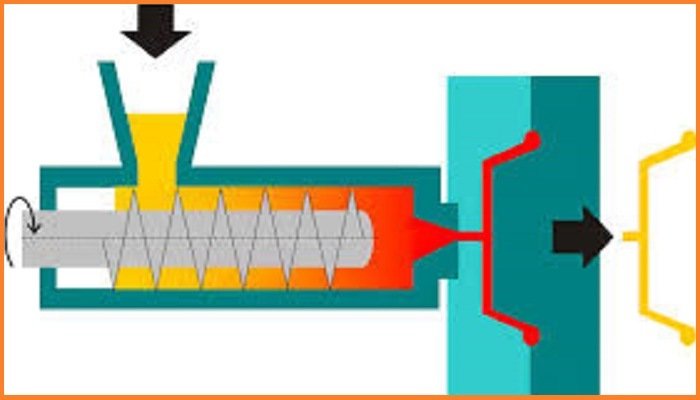

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. Nylon is a thermoplastic silky material that can be melt-processed into fibers, films or shapes.

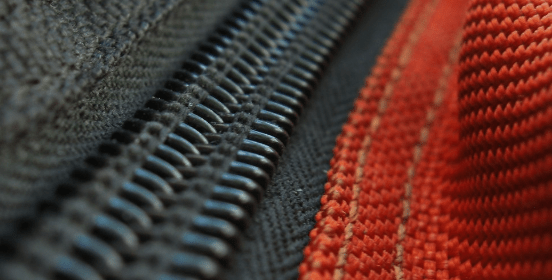

Nylon is made of repeating units linked by peptide bonds. Commercially, nylon polymer is made by reacting monomers which are either lactams, acid/amines or stoichiometric mixtures of di amines (-NH2) and di acids (-COOH). Mixtures of these can be polymerized together to make copolymers. Nylon polymers can be mixed with a wide variety of additives to achieve many different property variations. Nylon polymers have found significant commercial applications in fabric and fibers (apparel, flooring and rubber reinforcement), in shapes (molded parts for cars, electrical equipment, etc.), and in films (mostly for food packaging).

Chemistry

Nylons are condensation copolymers, formed by reacting di functional monomers containing equal parts of amine and carboxylic acid, so that amides are formed at both ends of each monomer in a process analogous to polypeptide biopolymers. Most nylons are made from the reaction of a dicarboxylic acid with a diamine (e.g. PA66) or a lactam or amino acid with itself (e.g. PA6). In the first case, the “repeating unit” consists of one of each monomer, so that they alternate in the chain, similar to the so-called ABAB structure of polyesters and polyurethanes. Since each monomer in this copolymer has the same reactive group on both ends, the direction of the amide bond reverses between each monomer, unlike natural polyamide proteins, which have overall directionality: C terminal → N terminal. In the second case (so called AA), the repeating unit corresponds to the single monomer.

Types of nylon

Nylon 66

Wallace Carothers at DuPont patented nylon 66 using amides. In the case of nylons that involve reaction of a diamine and a dicarboxylic acid, it is difficult to get the proportions exactly correct, and deviations can lead to chain termination at molecular weights less than a desirable 10,000 daltons (u). To overcome this problem, a crystalline, solid “nylon salt” can be formed at room temperature, using an exact 1:1 ratio of the acid and the base to neutralize each other. The salt is crystallized to purify it and obtain the desired precise stoichiometry. Heated to 285 °C (545 °F), the salt reacts to form nylon polymer with the production of water. Density is 1.15 gm/cc.

Nylon 6

Carothers overlooked the possibility of using lactams. That synthetic route was developed by Paul Schlack at IG Farben, leading to nylon 6, or polycaprolactam — formed by a ring-opening polymerization. The peptide bond within the caprolactam is broken with the exposed active groups on each side being incorporated into two new bonds as the monomer becomes part of the polymer backbone. The 428 °F (220 °C) melting point of nylon 6 is lower than the 509 °F (265 °C) melting point of nylon 66.

Nomenclature

The nomenclature used for nylon polymers was devised during the synthesis of the first simple aliphatic nylons and uses numbers to describe the number of carbons between acid and amine functions (including the carbon of the carboxylic acid). Subsequent use of cyclic and aromatic monomers required the use of letters or sets of letters. One number after “PA” for a homopolymer based on one monomer, and two numbers or sets of letters where there are two monomers. For copolymers the comonomers or pairs of comonomers are separated by slashes, as shown in the examples below.

Homopolymers :

PA 6 : [NH−(CH2)5−CO]n made from ε-Caprolactam.

PA 66 : [NH−(CH2)6−NH−CO−(CH2)4−CO]n made from hexamethylenediamine and adipic acid.

Copolymers:

PA 6/66: [NH-(CH2)6−NH−CO−(CH2)4−CO]n−[NH−(CH2)5−CO]m made from caprolactam, hexamethylenediamine and adipic acid.

PA 66/610 : [NH−(CH2)6−NH−CO−(CH2)4−CO]n−[NH−(CH2)6−NH−CO−(CH2)8−CO]m made from hexamethylenediamine, adipic acid and sebacic acid.

In common usage, the prefix ‘PA’ or the name ‘Nylon’ are used interchangeably and are equivalent in meaning.

The term polyphthalamide (abbreviated to PPA) is used when 60% or more moles of the carboxylic acid portion of the repeating unit in the polymer chain is composed of a combination of terephthalic (TPA) and isophthalic (IPA) acids.

Monomers

Nylon monomers are manufactured by a variety of routes, starting in most cases from crude oil but sometimes from biomass. Those in current production are described below.

Amino acids and lactams

- Caprolactam: Crude oil → benzene → cyclohexane → cyclohexanone → cyclohexanone oxime → caprolactam

- 11-aminoundecanoic acid: Castor oil → ricinoleic acid → methylricinoleate → methyl-11-undecenoate → undecenoic acid → 11-undecenoic acid → 11bromoundecanoic acid → 11-aminoundecanoic acid

- Laurolactam: Butadiene → cyclododecatriene → cyclododecane → cyclododecanone → cyclododecanone oxime → laurolactam

Diacids

- Adipic acid: Crude oil → benzene → cyclohexane → cyclohexanone + cyclohexanol → adipic acid

- Sebacic acid (decanedioic acid): Castor oil → ricinoleic acid → sebacic acid

- Terephthalic acid: Crude oil → p-xylene → terephthalic acid

- Isophthalic acid: Crude oil → m-xylene → isophthalic acid

Diamines

- Tetramethylene diamine (putrescine) Crude oil → propylene → acrylonitrile → succinonitrile → tetramethylene diamine

- Hexamethylene diamine (HMD): Crude oil → butadiene → adiponitrile → hexamethylene diamine

- 1,9-diaminononane: Crude oil → butadiene → 7-octen-1-al → 1,9-nonanedial → 1,9-diaminononane.

I decided to leave a message here on your Nylon | POLYMER WORLD page instead of calling you. Do you need more likes for your Facebook Fan Page? The more people that LIKE your website and fanpage on Facebook, the more credibility you will have with new visitors. It works the same for Twitter, Instagram and Youtube. When people visit your page and see that you have a lot of followers, they now want to follow you too. They too want to know what all the hype is and why all those people are following you. Get some free likes, followers, and views just for trying this service: http://v-doc.co/nm/39zu3 Unsubscribe here: http://corta.co/eXu