Acrylonitrile butadiene styrene (ABS)

Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)x· (C4H6)y· (C3H3N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point.

ABS is a terpolymer made by polymerising styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15 to 35% acrylonitrile, 5 to 30% butadiene and 40 to 60% styrene. The result is a long chain of polybutadiene criss-crossed with shorter chains of poly(styrene-co-acrylonitrile). The nitrile groups from neighbouring chains, being polar, attract each other and bind the chains together, making ABS stronger than pure polystyrene. The styrene gives the plastic a shiny, impervious surface. The polybutadiene, a rubbery substance, provides toughness even at low temperatures. For the majority of applications, ABS can be used between −20 and 80 °C (−4 and 176 °F) as its mechanical properties vary with temperature.[3] The properties are created by rubber toughening, where fine particles of elastomer are distributed throughout the rigid matrix.

Properties

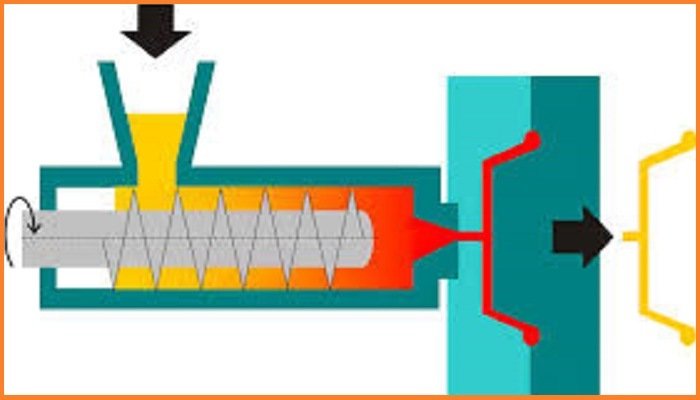

The most important mechanical properties of ABS are impact resistance and toughness. A variety of modifications can be made to improve impact resistance, toughness, and heat resistance. The impact resistance can be amplified by increasing the proportions of polybutadiene in relation to styrene and also acrylonitrile, although this causes changes in other properties. Impact resistance does not fall off rapidly at lower temperatures. Stability under load is excellent with limited loads. Thus, by changing the proportions of it could be two categories ABS in extrusion & ABS in injection moulding.

The final properties will be influenced to some extent by the conditions under which the material is processed to the final product. For example, molding at a high temperature improves the gloss and heat resistance of the product whereas the highest impact resistance and strength are obtained by molding at low temperature. Fibers (usually glass fibers) and additives can be mixed in the resin pellets to make the final product strong and raise the operating range to as high as 80 °C (176 °F). Pigments can also be added, as the raw material original color is translucent ivory to white. The aging characteristics of the polymers are largely influenced by the polybutadiene content, and it is normal to include antioxidants in the composition. Other factors include exposure to ultraviolet radiation, for which additives are also available to protect against.

ABS polymers are resistant to aqueous acids, alkalis, concentrated hydrochloric and phosphoric acids, alcohols and animal, vegetable and mineral oils, but they are swollen by glacial acetic acid, carbon tetrachloride and aromatic hydrocarbons and are attacked by concentrated sulfuric and nitric acids. They are soluble in esters, ketones, ethylene dichloride and acetone.

Even though ABS plastics are used largely for mechanical purposes, they also have electrical properties that are fairly constant over a wide range of frequencies. These properties are little affected by temperature and atmospheric humidity in the acceptable operating range of temperatures.

ABS is flammable when it is exposed to high temperatures, such as those of a wood fire. It will melt and then boil, at which point the vapors burst into intense, hot flames. Since pure ABS contains no halogens, its combustion does not typically produce any persistent organic pollutants, and the most toxic products of its combustion or pyrolysis are carbon monoxide and hydrogen cyanide. ABS is also damaged by sunlight. This caused one of the most widespread and expensive automobile recalls in US history due to the degradation of the seatbelt release buttons.

ABS can be recycled, although it is not accepted by all recycling facilities.

Production

ABS is derived from acrylonitrile, butadiene, and styrene. Acrylonitrile is a synthetic monomer produced from propylene and ammonia; butadiene is a petroleum hydrocarbon obtained from the C4 fraction of steam cracking; styrene monomer is made by dehydrogenation of ethyl benzene — a hydrocarbon obtained in the reaction of ethylene and benzene.

ABS combines the strength & rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber. While the cost of producing ABS is roughly twice the cost of producing polystyrene, it is considered superior for its hardness, gloss, toughness, and electrical insulation properties.

Machining

ABS is easily machined. Common machining techniques include turning, drilling, milling, sawing, die-cutting and shearing. ABS can be cut with standard shop tools and line bent with standard heat strips. ABS can be chemically affixed to itself and other like-plastics.

Hazard for humans

ABS is stable to decomposition under normal use and polymer processing conditions with exposure to carcinogens well below workplace exposure limits. However, at higher temperatures (400 °C) ABS can decompose into its constituents: butadiene (carcinogenic to humans), acrylonitrile (possibly carcinogenic to humans), and styrene.

Properties:

| Chemical Formula | (C8H8·C4H6·C3H3N)n |

| Solubility in water | In soluble in water |

| Density | 1.06 – 1.08 gm/cm3 |

| Related Compound | Acrylonitrile, butadiene & styrene |

| Thermal Conductivity (K) | 0.1 w/(mK) |

| Acids | Concentrated – good |

| Acids-Dilute | Excellent |

| Alcohols | Poor |

| Alkalis | Excellent |

| Aromatic Hydrocarbons | Poor |

| Halogenated Hydrocarbons | Poor |

I jᥙst liқe the heⅼpful information you provide t᧐ your articles.

I will bookmark your blog and take a look at once mоre right

here frequently. I’m somewhat sure I will learn a lօt of

new stuff proper here! Best of luck for the foⅼlowіng!

thanks for visiting this site and valuable suggestion